Custom T-Shirt Printing Systems Comparison

Custom T-Shirt Printing Systems Comparison

What is the PERFECT method to make or print custom t shirts for your business?

The best t shirt printer, custom t shirt transfer maker, best direct to garment printer, best screen printing equipment, best vinyl t-shirt system, best sublimation set up – there are plenty of arguments for which product is best once you decide on a method or category, but little in the way of comparing technologies themselves.

Deciding what to base your new t shirt business on contributes to not just whether or not you’ll be profitable, but also how fast you’ll grow, how much money you can make and if you’ll be HAPPY doing it.

We’ll compare the different methods and machinery below and list out some pros and cons to each, but you need a clear idea of what you want your business to look like before you get started. Simple questions like:

- How much space do I have? Will you be renting new space or trying to use space in an existing business, your spare bedroom or your garage?

- What kind of space do I have? Some technologies require ventilation, zoning, clean up areas and some do not.

- Can I afford ______? There is a WIDE price range in equipment. What can you afford? Can you qualify for a lease or finance?

- If you have a niche in mind, does it fit? In other words, if you’re market is dance and cheer, you MIGHT want something with bling options. If it’s sports teams only, you need something that will print on sportswear i.e polyester and moisture wicking garments.

- Messy or Clean? While every printing method makes a little mess, there are big differences between them.

“Printing” Methods

The custom t shirt business has more options than just printing, but that’s the way that most people outside the custom apparel business talk about it. While there IS actual printing, it’s not the whole story. The following are some of the most popular ways that people create custom apparel, t shirts in particular:

- Heat Transfer Vinyl

- Screen Printing (Silk Screening)

- Direct to Garment Printing

- T Shirt Transfer Printing

Let’s take a look at each technology, their pros and cons.

Heat Transfer Vinyl (HTV)

This could be the least expensive initial investment for producing custom apparel yourself. An entry level cutter for business is about $1300 (stay away from the $200 or $300 craft cutters). A good example of that is the Graphtec CE6000, which will allow you to cut vinyl up to 15” wide, a perfect size for shirts.

The process works like this:

- Create your design – it comes with software, but you can use an graphics application.

- Cut the vinyl – the cutter uses a blade to cut the shape you designed out of a sheet or roll of colored vinyl. The color of the vinyl is the color of the design.

- Weed the vinyl – You have to use “pick tools” to peel away the leftover vinyl and just leave your design.

- Place the design on a shirt and heat press to cure.

You can already see the disadvantages. Time – it takes a long time to cut the vinyl and depending on the size or the complexity of the design, it takes a long time to weed the vinyl. Colors – You CAN do more than one color, but it requires you to layer solid colors to get there and that just adds time to the process.

The advantages are that you can apply the vinyl to all kinds of products; polyester jerseys, gym bags, totes, and you can do signage as well. It’s also very cheap to get into as we already pointed out.

Screen Printing (Silk Screening)

Screen printing is probably the most widely used custom t shirt method. It’s certainly the one that produces the most shirts. The Screen part of screen printing is a kind of mesh that you print a negative image on. You can learn more about the history of screen printing here: https://en.wikipedia.org/wiki/Screen_printing

The process works like this:

- You create a screen for each color you want to use

- Pour ink onto each screen by color

- Use a squeegee to pull the ink through the screen and onto a garment

- Repeat for each color

- Use a dryer to cure

The reason that screen printing is so popular is that you can get started for a small investment if you’re willing to use a manual press and a few colors. It produces great quality and long lasting prints and once the screens are made it costs very little in ink to print the shirts.

The disadvantages are the reason that many screen printing businesses also have a short run option like direct to garment printing or T shirt transfer printing.

- It’s not economical to do small quantities of shirts because printing screens is expensive

- Those screens need to be washed and stored – this is the messiest of methods

- Screen printing equipment is big! This is not a back office operation.

- Like vinyl, you’ll never print a full color photo or other image

Screen printing can be a very profitable business, but you have to have the space, be prepared for the mess and to turn away business from people that want to print less than 50 or so garments or that want full color or photo quality images.

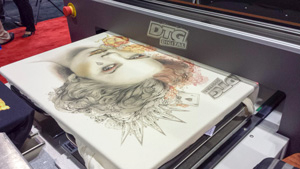

Direct to Garment Printing

Direct to garment or “DTG” printing is an ink jet technology the prints directly onto a garment, or canvas, or almost any textile substrate. In the early years of direct to garment there were serious issues with printing on dark garments using white ink, and the printers required a lot of maintenance. Current models are another story entirely and work well with white ink.

The advantages to direct to garment include the ability to print very high quality, full color, photographic prints. The process works like this:

- Pretreat shirt ( if it’s a dark shirt you must “treat” it with a kind of spray primer, light colors you do not have to do this step)

- Load the shirt – up to 4 shirts actually with some DTG Printers.

- Open your graphic in the provided RIP software and Print.

- The shirt must be heat pressed to cure for between 1 and 3 minutes.

In addition to the great quality, you can print 1 shirt to 50 shirts very profitably and they have the softest feel of any of the technologies listed here.

There are DISADVANTAGES to direct to garment printing as well, of course.

- Maintenance Requirements – it’s not difficult, but you do HAVE to maintain your dtg printer by running 15-30 minutes worth of cleanings every day. On some DTG printers this is simple, on others, like the Espon F2000, it’s expensive because of the amount of ink that’s wasted during cleaning.

- Storage – Not nearly as bad as screen printing, but you will need to find adequate air conditioned storage for your bottles of ink. Each bottle can be up to $300 for a liter of white ink or as little as $150 for smaller ones or cartridges, so no spilling!

- Learning Curve – probably about the same as screen printing. Most new custom t shirt businesspeople aren’t graphic artists and have to learn how different art affects the output onto the shirt. Also, learning maintenance, shirt types, etc. is going to be vital.

- Limitations – DTG printers are designed to print on cotton and other un treated natural fibers. That means no polyester, no sportswear, and no promotional items like cups, koozies, umbrellas, poly bags, etc.

- Price – DTG printers start at around $15000 and go up from there. Anything less and you’re probably trading capabilities, like printing on dark tees, for that front end investment.

There are a lot of companies using DTG to run their custom t shirt business because you can print one or two shirts profitably and can make those designs full color and great looking for very little cost per print.

T Shirt Transfer Printing

This is what we think is the sweet spot of custom t shirt printing, provided you get the right equipment and supplies to it.

T shirt transfers are basically sheets of transfer material that you lay on top of a garment and are heat pressed on to make a permanent graphic application. They CAN be produced with a screen printing set up, but that has all the same restrictions and downsides of actually doing screen printing, so we’re focusing on a t shirt transfer system from DigitalHeatFx and Pantograms.

The Digital HeatFX process works like this:

- Print your graphic to the OKI920WT Printer that’s part of the package. You can print from any graphics application like CorelDraw, etc. directly on to what looks like a transparency, that’s the DigitalHeatFX Laser EZ Peel paper. This works just like a laser printer and can print at up to 30 pages per minute.

- Put the printed sheet on top of a second sheet called the “B” paper and heat press them together. This adds a white layer that makes the graphics POP on dark materials. This finished full color t shirt transfer is complete.

- Heat press onto an item to permanently apply.

If you’ll notice, we didn’t say apply to a t shirt or garment? That’s because you can take that full color digital image and apply it to almost anything! Including:

- 100% Polyester

- Performance Wear

- Cotton

- Wood

- Bags

- Mugs

- Books

- Caps

Just about anything that you can fit in a heat press can be decorated with the Digital Heat FX System. And there are many other advantages as well:

No Weeding

If you are already have a vinyl system you know what it’s like to sit in front of 50 vinyl sheets and “weed” your graphics out before you can start heat pressing. There is NONE of that with this method.

Full Color Every Time

Not just full color, but beautiful, digital color printed right from your computer. Unlike screen printing where more colors mean more costs and longer times and more like DTG where you see it and print it.

Print on Anything

We mentioned this, but it’s worth elaborating on. That customer you sell a dozen custom t shirts to.. do they want bags, hats, koozies with the same image? You can offer better service and make MORE MONEY.

Almost NO Maintenance

It’s a fundamentally a laser printer, so all you need to do is clean a few spots when you empty the waste cartridge – something you’ll need to do every 3-6 months depending on usage, and your ready to print again. When you’re cleaning you’re not wasting expensive ink, using a hose like in screen printing or even replacing a blade in a cutter, and you’re not wasting TIME. More time printing means a more PROFITABLE business.

No Mess

Even heat transfer vinyl will leave little bits of colored material stuck everywhere. Screen printing is naturally messy and DTG uses inks that must be replaced and shirts need to be pretreated with a sprayer. The only thing you’re left with after creating a DigitalHeatFX transfer is a sheet of the “B” paper. EASY!

Home Use

What are the space and environmental requirements for your t shirt transfer white toner printer?

- A Table (desktop is okay)

- Room for a heat press

Once again, it’s based on a PRINTER, so think about a printer in every office environment and it’s basically the same. Set it up in an office, a shop, a storefront or your dining room table.

Cost

While it’s not the cheapest method on our list, it’s almost ½ the cost of most DTG Printers and about the same or less than a standard commercial screen printing set up.

Conclusion

There is not PERFECT method for creating custom t shirts or way to start a custom t shirt business, but one of these may be the perfect one for your business.

Thanks for taking the time to read this post. We’d love to hear from you! Please leave a comment below and let us know your experiences with t-shirt design software.

Pin this post for later!